Building a Line Following Robot

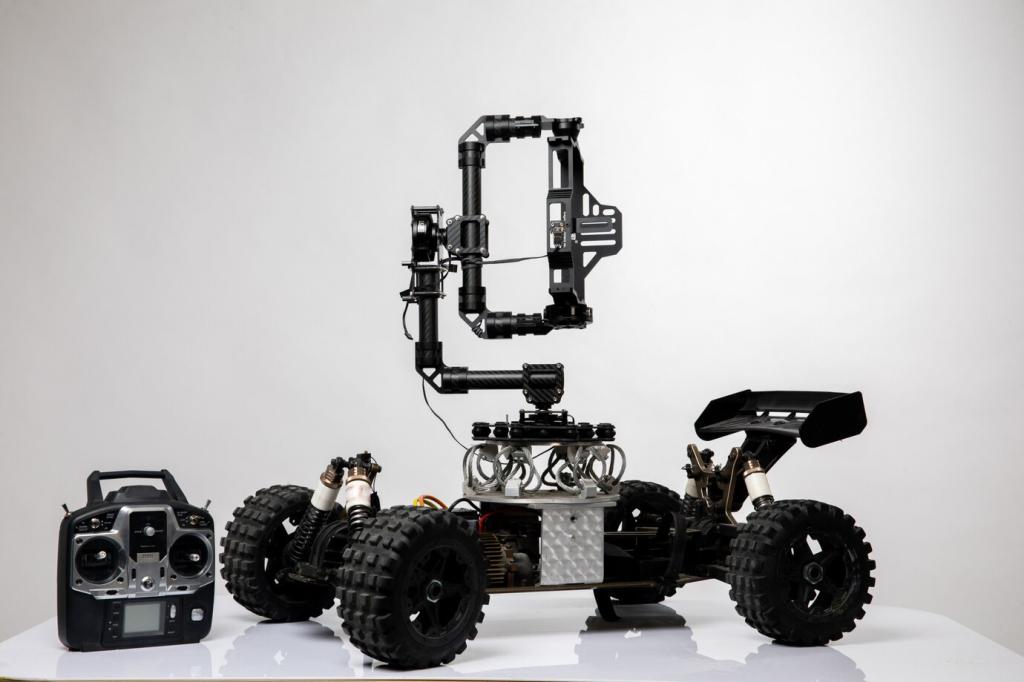

Building a line following robot is an engaging entry point into robotics, combining electronic hardware, logical programming, and mechanical design into one cohesive project. The process of constructing such a robot not only helps you understand how basic sensors and actuators work together, but also develops problem-solving skills that are essential in robotics. Whether you are a student, educator, or hobbyist, this guide will walk you through the fundamental concepts and steps required to design, assemble, and program a robot that can autonomously follow a marked path.

Core Functionality and Principles

At the heart of a line following robot is the interplay between its sensors, control logic, and actuators. The robot uses sensors, often infrared or optical, to monitor the surface beneath it and detect the contrast between the desired path and the floor. When the sensors detect deviation from the line, the robot’s control algorithm computes appropriate corrections and directs its motors to steer back onto the path. Through this feedback loop, the robot can navigate curves, intersections, and complex patterns. Mastery of this basic principle enables scaling up to more sophisticated navigation tasks in autonomous robotics.

Typical Applications and Educational Value

Line following robots are not only used for novelty or demonstration—they also serve vital educational and practical purposes. In classrooms and robotics clubs, these robots enable students to experiment with real-world sensing, decision-making algorithms, and mechanical design. Beyond education, line following systems form the backbone of automated guided vehicles (AGVs) employed in warehouses and manufacturing lines. Mastering the construction and programming of such robots provides foundational expertise that is transferable to more advanced robotic and automation projects.

Challenges in Design and Implementation

Designing a line following robot can present several technical and practical challenges. One common hurdle is ensuring sensor accuracy in varied lighting conditions or when the path is interrupted. Another significant consideration is the development of an effective control algorithm, which must make timely decisions to keep the robot on track without oscillation or instability. Additionally, mechanical issues such as motor torque, wheel alignment, and chassis balance can impact performance. Addressing these challenges through thoughtful design and iterative testing is an integral part of developing a successful line following robot.

Key Components of a Line Following Robot

Sensors for Path Detection

Sensors are arguably the most critical element of any line following robot, tasked with distinguishing the marked path from the surrounding surface. Commonly, infrared reflectance sensors or light-dependent resistors are used to sense changes in reflectivity between the line and the floor. Accuracy, responsiveness, and placement of these sensors are vital; multiple sensors may be required to reliably interpret the line’s position, especially around curves or at intersections. Calibration and mounting are equally important, as these determine how well the sensors can detect transitions and enable the robot to make real-time adjustments.

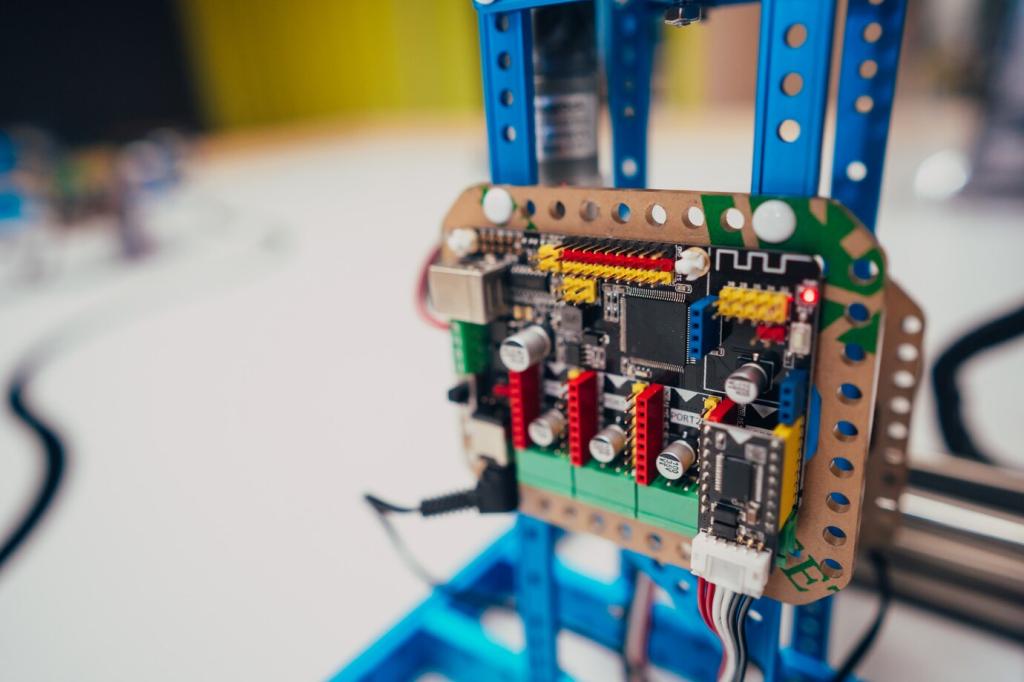

The Role of Microcontrollers

The microcontroller serves as the brain of the robot, processing inputs from the sensors and executing programmed logic to control the actuators. Popular choices include Arduino, Raspberry Pi, and similar embedded platforms, favored for their accessibility and widespread community support. The microcontroller reads sensor values, applies control algorithms—such as simple conditional logic or more advanced PID controllers—and generates output signals for steering and propulsion. Efficient programming and a robust hardware setup ensure that the robot responds quickly and accurately to changes in the line’s path.

Developing the Control Logic

Control logic is the heart of your robot’s behavior. The most straightforward implementation checks each sensor’s state, steering left or right when the line shifts under the robot. However, this method can result in overshooting or jittery motion, especially at higher speeds or around sharp bends. For smoother and more accurate tracking, many builders use proportional-integral-derivative (PID) control, which dynamically adjusts motor speeds in proportion to the error detected by the sensors. Crafting effective control logic involves not only programming skills but also intuitive understanding of sensor placement and the robot’s physical characteristics.

Code Optimization and Calibration

After the initial code is written, optimization and calibration are essential to enhance robustness and efficiency. Calibrating sensors ensures that the robot distinguishes the line against varying backgrounds and lighting conditions. Adjusting motor speed parameters helps in achieving a balance between speed and accuracy. Fine-tuning PID control constants, if used, can greatly improve the robot’s responsiveness and minimize oscillations. Through iterative testing and incremental code refinement, the robot’s performance can be significantly improved, making line following smooth and reliable even under challenging conditions.

Troubleshooting and Enhancements

Programming a line following robot invariably involves debugging and experimentation. Common issues include inconsistent sensor readings, incorrect motor responses, or instability when transitioning over gaps or curves. Systematic troubleshooting—breaking down problems into sensor, code, and mechanical subsystems—enables efficient identification of root causes. Once basic line following is robust, enhancements like speed boosts, path memory, or obstacle avoidance can be added for more exciting and challenging performance. Each refinement brings new insights into robotics and builds confidence for tackling increasingly complex projects.